In the realm of precision manufacturing, every micron matters. The quest for accuracy and efficiency has driven the development of cutting-edge technologies, and one such breakthrough is the QMT220, a remarkable system from Quantum Machine Tools.

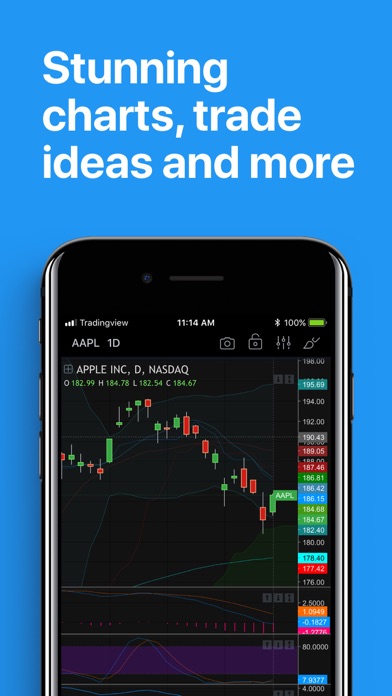

Image: hedavagor.wordpress.com

The QMT220 represents a leap forward in machining capabilities, integrating state-of-the-art components and innovative design principles to deliver exceptional performance. Its unique features and versatility make it an ideal choice for a wide range of applications, from aerospace and automotive to medical and electronic industries.

Quantum Leap in Precision

Multi-axis Control with Enhanced Motion Accuracy

The QMT220 employs a sophisticated multi-axis control system that precisely coordinates the movements of its axes. Utilizing advanced algorithms and sensors, it ensures a level of motion accuracy that is unachievable by conventional methods.

State-of-the-art Spindle and Tooling

Equipped with a high-speed spindle and a range of precision tooling, the QMT220 performs complex machining operations with exceptional precision and surface finish. Its advanced spindle technology minimizes vibration and chatter, allowing for smooth and efficient cutting of even the most demanding materials.

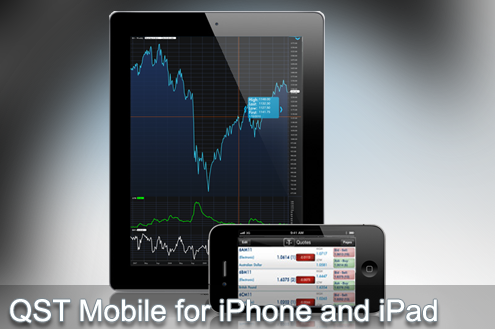

Image: qstrp.quicksuitetrading.com

Comprehensive Overview

Definition

Quantum Machine Tools’ QMT220 is a fully integrated precision machining system that combines the latest hardware and software technologies. It offers a comprehensive suite of features designed to enhance productivity and accuracy in advanced manufacturing processes.

History and Evolution

The development of the QMT220 is a culmination of decades of research and innovation in precision machining. Quantum Machine Tools has consistently pushed the boundaries of technology, resulting in the creation of this groundbreaking system that sets new standards for the industry.

Significance in Manufacturing

The QMT220 has revolutionized precision manufacturing by enabling the production of parts with unprecedented accuracy and efficiency. Its capabilities have made it an invaluable tool for manufacturers seeking to enhance product quality, reduce production costs, and keep pace with the demands for advanced technologies.

Latest Trends and Developments

Industry 4.0 Integration

The QMT220 seamlessly integrates with Industry 4.0 technologies, allowing manufacturers to achieve digitalization and automation in their production processes. Its connectivity and data analytics capabilities provide real-time monitoring and optimization, enabling predictive maintenance and enhanced efficiency.

Advanced Visualization and Modeling

Virtual reality (VR) and augmented reality (AR) are transforming the way engineers and machinists interact with the QMT220. These immersive technologies allow for improved visualization of complex designs, remote monitoring, and even personalized training experiences.

Tips and Expert Advice

Invest in High-Quality Cutting Tools

Maximize the performance of the QMT220 by investing in high-quality cutting tools that are specifically designed for your applications. This will not only ensure optimal tool life but also contribute to the precision and consistency of your machining processes.

Utilize Preventative Maintenance

Regular preventative maintenance is crucial to maintain the long-term accuracy and performance of the QMT220. Implement a comprehensive maintenance plan that includes regular cleaning, lubrication, and inspections to minimize downtime and ensure peak operation.

Frequently Asked Questions

Q: What materials can the QMT220 machine effectively?

A: The QMT220 can handle a wide range of materials, including metals, composites, plastics, and ceramics, making it versatile for various manufacturing applications.

Q: What is the maximum speed and accuracy that the QMT220 can achieve?

A: The QMT220’s high-speed spindle and advanced control system enable exceptional speed and accuracy, meeting the demands of demanding machining operations and ensuring precise and consistent results.

Q: What is the level of training required to operate the QMT220?

A: While some prior experience in machining is beneficial, Quantum Machine Tools provides comprehensive training programs tailored to different skill levels to ensure that operators can utilize the full capabilities of the QMT220 effectively and safely.

Http Www.Options-Trading-System.Com Pc Qmt220

Image: fity.club

Conclusion

Quantum Machine Tools’ QMT220 is a testament to the relentless pursuit of precision and efficiency in manufacturing. Its advanced technology and comprehensive capabilities empower manufacturers to achieve new heights of quality and productivity. Whether you’re a seasoned machinist or a manufacturer looking to gain a competitive edge, the QMT220 is an investment that will undoubtedly transform your production processes.

Are you ready to explore the transformative possibilities of the QMT220? Contact Quantum Machine Tools today to learn more and take your manufacturing operations to the next level.